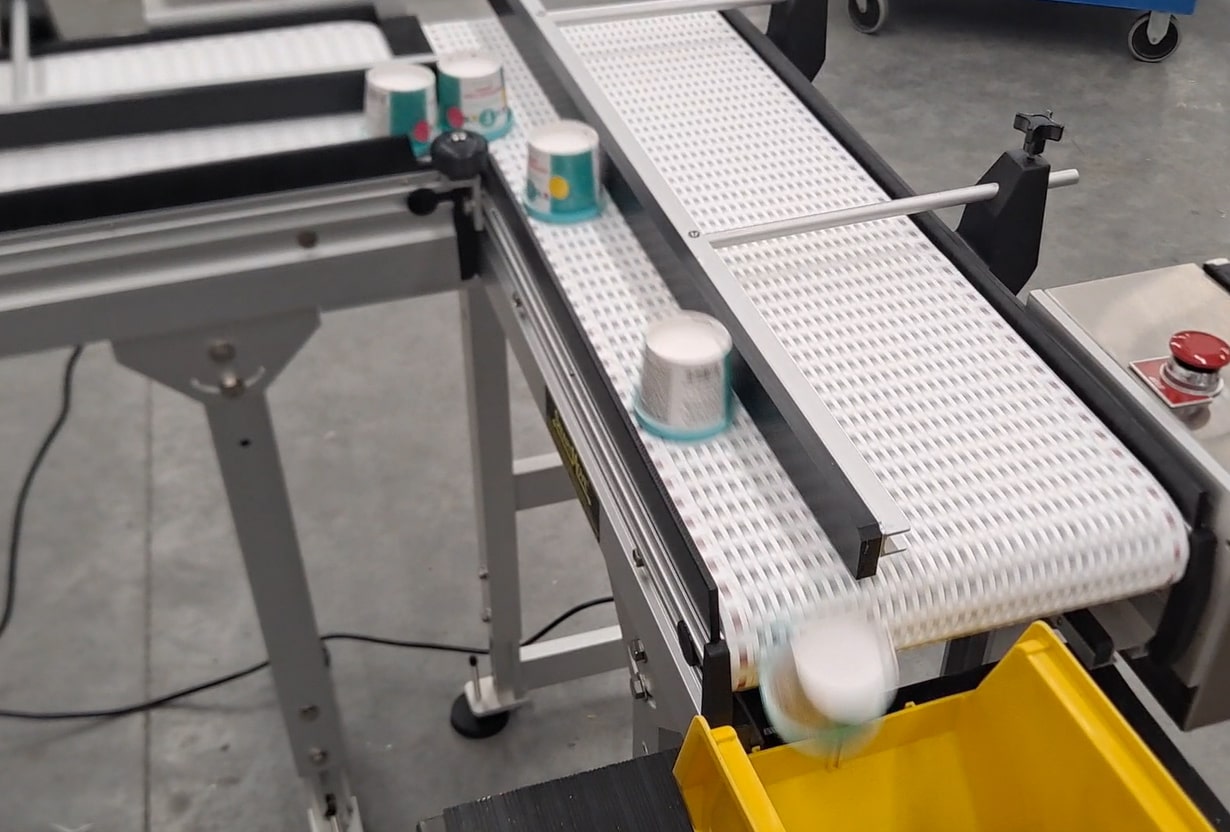

High Speed Singulation

Singulation is an important part of food & drug production. Each product must go into the metal detector one at a time. The singulation process is an easy task for SmartMove® Singulating Conveyors due to the sliding belt system. The items are dropped out of the machine, take two 90 degree turns and singulate. The smooth 90 degree turn does not spill product but can reach a high rate of flow and increase your production line.

90 Degree Turn Conveyor Experts

Benefits of 90° Turns with SmartMove® Modular Universal Conveyor Sections:

- Flexible Placement: Create turns anywhere by positioning conveyor ends perpendicularly. Remove a section of guard rail (saw required) on the receiving conveyor. For improved performance, install our “tilting” end-to-side transfer plates.

- Versatile Product Handling:

1. Flat-bottomed items transfer easily at corners.

2. For non-flat items, elevate the drop-end conveyor for a “waterfall” effect. - Cost-Effective: Approximately half the initial cost of a power turn, with reduced maintenance requirements.

- Key Features:

1. Portable

2. Quiet operation

3. Clean design

4. Modular construction

5. Safe to use

6. Energy efficient

7. Low maintenance - Efficiency Benefits:

1. Extended conveyor lifespan

2. Improved safety due to smaller motor size - Streamlined Process:

1. Easy ordering

2. Quick shipping

3. Simple installation

4. Factory-direct pricing

Each 90 degree turn conveyor system is custom built to order by our expert team of engineers.

Call 1-800-581-2876 to order your SmartMove® Modular Conveyor system now.

Click here to see all conveyor system types manufactured by Smartmove®