ALL MATERIALS ARE FDA APPROVED.

Standard Belting

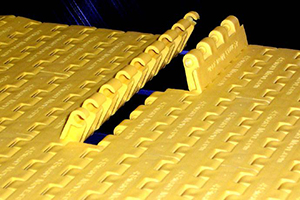

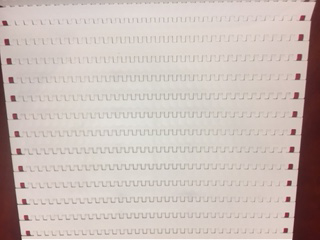

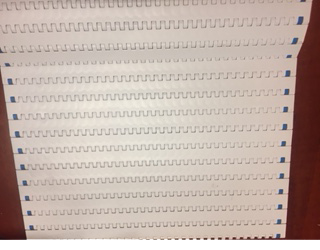

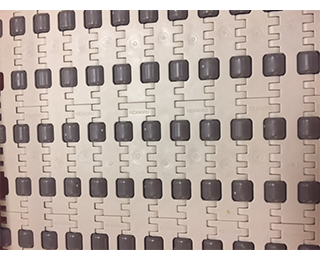

Accumulation Belting – Rollers

Accumulation Belting – Rollers

Low friction belting-optimized to accumulate and lineonvey cases, cartons, totes and multi-packs in various materials including cardboard, lithographed cardboard, plastic, paper, fiberglass and shrink wrap. The new, high density roller design produces a more stable accumulating surface to accumulate your product with no damage to the package surface.

High density roller design produces a more stable accumulating surface to accumulate your product with no damage to the package surface.

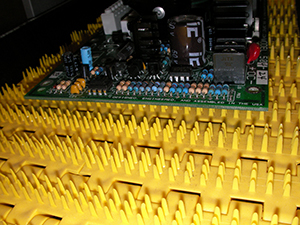

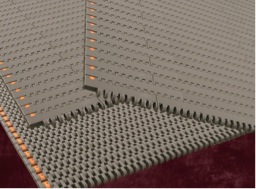

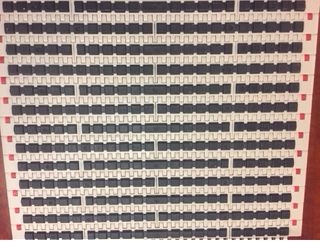

Flat Top Pinned Belting

Flat Top Pinned Belting

For heavy loads: high performance pins for higher speeds and longer wear life.

Closed hinge design is ideal for container handling and decreases pin wear and chain elongation.

These highest quality of products improve energy, reduce waste, improve safety and deliver a dependable product for operation. Our design engineers provide the expert advise to optimize your specific application.

Food belting – FDA and USDA approved belting.

Rubber Top Belting

Rubber Top Belting

High Friction belting designed for incline and decline conveyors. Used for secure handling. Maintains pack spacing and prevents package skewing during conveyor transfer. FDA approved materials, pusher attachment available, self-cleaning. No lubrication needed.

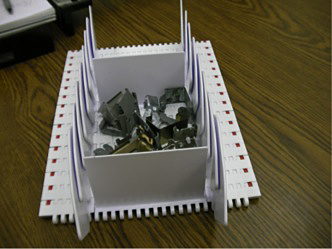

Custom belting – for any application.

Custom belting – for any application.

Let our experts decide which belting would be most appropriate for your application. Many belts for different applications are readily available and interchangeable which makes SmartMove Conveyors the most modular conveyor on the market today.

If you don’t see a particular belt you may be looking for, please don’t hesitate to ask our consultants.

21% opening, pinned belting, 180 Degrees Fahrenheit dry 150 deg Fahrenheit wet, chain strength 2000 per foot, FDA approved to FDA 21 CFR 177 (used for cooling and washdown)

21% opening, pinned belting, 180 Degrees Fahrenheit dry 150 deg Fahrenheit wet, chain strength 2000 per foot, FDA approved to FDA 21 CFR 177 (used for cooling and washdown) High temp white pinned belting, 220 deg Fahrenheit dry, 212 deg Fahrenheit wet, chain strength 1080 lbs per foot, FDA approved to FDS 21 CFR 177

High temp white pinned belting, 220 deg Fahrenheit dry, 212 deg Fahrenheit wet, chain strength 1080 lbs per foot, FDA approved to FDS 21 CFR 177 Rubber Top High Friction Pinned belting, self cleaning, chain strength 920 lbs per foot

Rubber Top High Friction Pinned belting, self cleaning, chain strength 920 lbs per foot Low temp pinned belting 100 deg Fahrenheit max, 80 deg Fahrenheit wet, chain strength 800 lbs per foot, FDA approved to FDA 21 CFR 177 (used for food application for flash freezing)

Low temp pinned belting 100 deg Fahrenheit max, 80 deg Fahrenheit wet, chain strength 800 lbs per foot, FDA approved to FDA 21 CFR 177 (used for food application for flash freezing) High performance pinned belting with low backline pressure rollers, 180 de Fahrenheit dry, 150 deg Fahrenheit wet, chain strength 775 lbs, FDA approved to FDA CFR 177

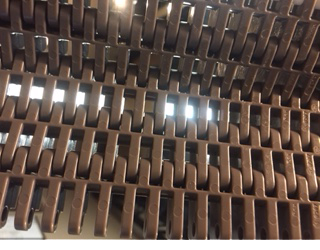

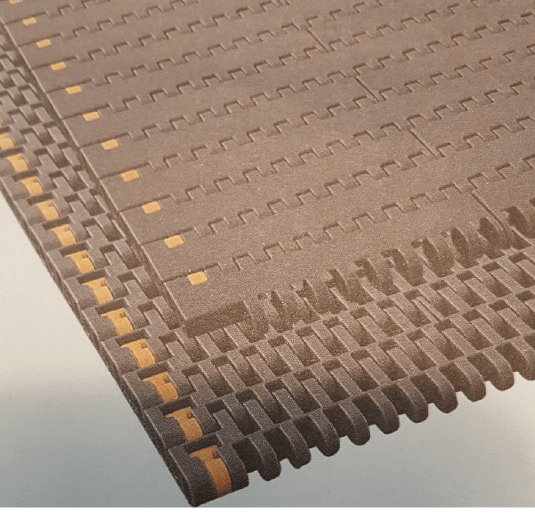

High performance pinned belting with low backline pressure rollers, 180 de Fahrenheit dry, 150 deg Fahrenheit wet, chain strength 775 lbs, FDA approved to FDA CFR 177 RX-HP8505 High Performance (HP) Pinned Belt, internally lubricated acetal, Brown, Sold Per foot. HP materials can reduce wear up to 40% over plain acetal and 25% over low friction acetal. 180 deg fahrenheit dry, 150 deg fahrenheit wet, Chain Strength 2000 lbs per foot, FDA approved to FDA 21 CFR 177.

RX-HP8505 High Performance (HP) Pinned Belt, internally lubricated acetal, Brown, Sold Per foot. HP materials can reduce wear up to 40% over plain acetal and 25% over low friction acetal. 180 deg fahrenheit dry, 150 deg fahrenheit wet, Chain Strength 2000 lbs per foot, FDA approved to FDA 21 CFR 177.

Call or email sales@4smartmove.com to discuss the best belting for your SmartMove Conveyor.

CLICK HERE to “Spec Out” a custom conveyor system. Built to order & shipped out fast.