MODULAR CONVEYOR SYSTEMS – BUILT TO ORDER

MODULAR CONVEYOR SYSTEMS – BUILT TO ORDER

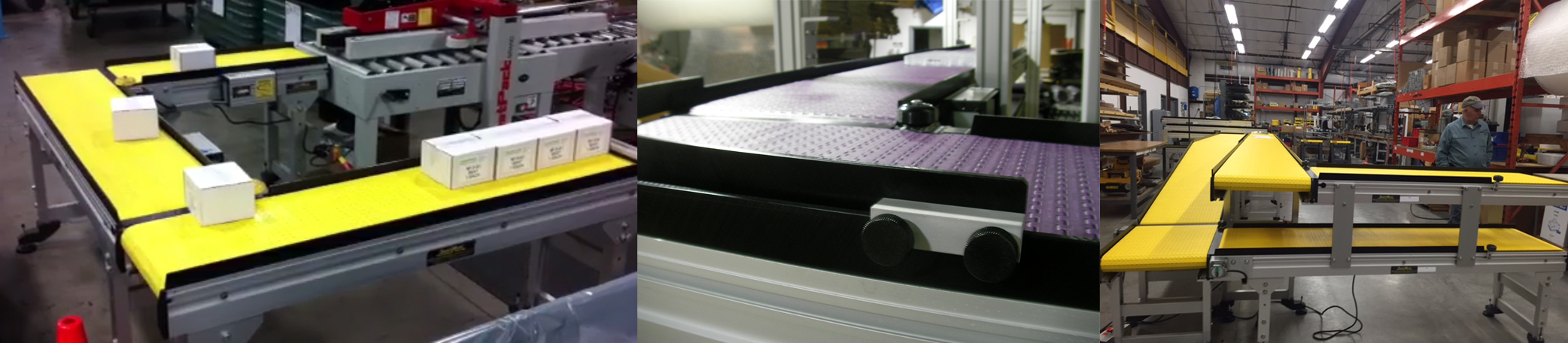

SmartMove Conveyors modular conveyor systems are uniquely suited for creating custom conveyor solutions. Using combinations of SmartMove’s standard accessories, and the creation of custom accessory solutions, SmartMove Conveyors can rapidly adapt to any conveyor need. For help with custom solutions, call us at 1-800-581-2876 or use the contact form on the website.

CLICK HERE to “Spec Out” a custom conveyor system. Built to order & shipped out fast.

MODULAR CONVEYORS DONE RIGHT

Modular conveyors are a type of conveyor system that is made up of individual modules that can be easily connected to create a custom conveyor system that meets the specific needs of a particular application. These systems are designed for both manufacturing and material handling settings and can transport various materials, products, boxes and packaging.

SmartMove® Conveyors Modular Conveyors

SmartMove® Conveyors modular conveyors are highly versatile and can be used in a wide range of applications. They are ideal for use in manufacturing facilities, warehouses, distribution centers, and other industrial settings. They can be used to transport a wide range of products, including food, pharmaceuticals, electronics, and more.

Why SmartMove®?

Comparing us to other manufacturers? Here are the top 10 reasons why companies choose SmartMove®:

- Customizable conveyor systems: SmartMove® offers custom-engineered conveyor systems that can be tailored to your exact specifications in a matter of days.

- Plug-and-play design: The modular conveyors are plug-and-play, which means they can be assembled without technicians and require no maintenance.

- Versatile configurations: The conveyor systems can be configured in a variety of ways, including short line, long line, multi-level, weigh scale, accumulation, batch counting, spacing, or carousel.

- Safe and efficient: The solid surface work station conveyor systems are safe, clean, and efficient, making them ideal for use in a variety of industries, including pharmaceuticals, food, electronics, and automotive.

- High-speed pick and pack: SmartMove® offers high-speed pick and pack solutions using Kawasaki Y series Delta Robots and RS007N Robot SmartMove Conveyor.

- Multi-lane conveyor: The “carousel-style” recirculating multi-lane conveyor system allows products to change direction on the belt.

- On-site technical assistance: SmartMove® provides on-site technical assistance, on-site start-up, turnkey services, and systems training.

- Customized belting: The company offers custom belting for new or existing conveyor systems, including accumulation, flat top pinned, cooling, rubber top, ribbed, FDA approved, and ESD.

- Made in the USA: All conveyor systems are manufactured in the USA, ensuring high quality and fast delivery times.

- Customer testimonials: SmartMove® has received positive feedback from satisfied customers, who praise the company’s efficiency, reliability, and excellent customer service.

Benefits of Modular Conveyor Systems

One of the key benefits of SmartMove® modular conveyors is their flexibility. They can be easily reconfigured to meet changing production needs, making them ideal for use in dynamic manufacturing environments. They can also be easily expanded or modified as production needs change, allowing businesses to scale their operations as needed.

Another benefit of modular conveyors is their ease of maintenance. Because they are made up of individual modules, it is easy to replace or repair individual components as needed. This can help to minimize downtime and reduce maintenance costs over time.

Modular conveyors are also highly efficient. They can be designed to transport products at high speeds, which can help to increase productivity and throughput. They can also be designed to handle a wide range of product sizes and shapes, making them ideal for use in a variety of applications.

When it comes to selecting a modular conveyor system, there are a number of factors to consider. These include the size and weight of the products being transported, the speed at which they need to be transported, and the specific requirements of the application. Other factors to consider include the available space for the conveyor system, the layout of the facility, and the budget for the project.

Versatile Conveyor Systems

Overall, modular conveyors are an excellent choice for businesses looking to improve their packaging order fulfillment or material handling operations. Modular conveyor systems by SmartMove® are highly versatile, efficient, and easy to maintain, making them an ideal choice for a wide range of applications.