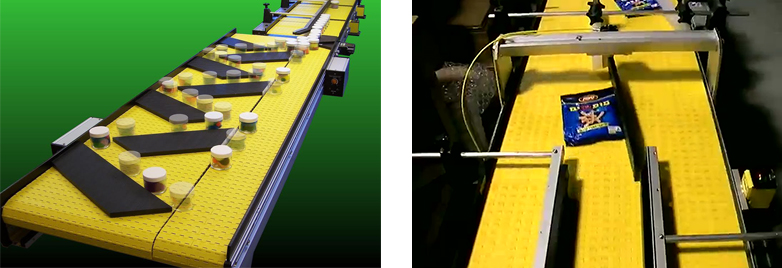

Sorting Conveyors Increase Productivity

Sorting items for packaging by hand is time consuming and prone to human error. Eliminate mistakes by installing a SmartMove® Conveyor that sorts and counts items for packaging and outbound order fulfillment. This will improve quality control while facilitating easier handling and most importantly, eliminating costly overshipment errors. In terms of operational efficiency, SmartMove® Conveyors always create cleaner work flow and a safer environment for employees.

Sortation At Any Speed

SmartMove can accommodate many types of sorting processes, as our modular plastic chain belt conveyors allow for complex package handling processes like indexing, shingling, singulating and aligning or orientation of items.

We create a system around your needs taking into account the size, shape and weights of items that require precise sortation as well as the rate (speed) needed on the line. We can also setup multiple diverts on the same line for sorting or pushing. Items can be transferred off either side of the conveyor belting to other conveyors or workstations. Variable speed motors ensure that your employees can adjust belt speed to match the volume of items required. Our ”Sorting Conveyor” systems easily handles processing of heavy items at low, medium or high speeds. Sortation is the process of separating items to specific lanes with the purpose of arranging product for packaging. Sortation conveyor systems are often employed when a high volume of items need to be moved into different destinations for further processing.

Built To Last

SmartMove® Conveyors modular snap link plastic chain sorting conveyors provide a long service life, and feature quiet, maintenance free operation.

CLICK HERE to “Spec Out” a custom conveyor system. Built to order & shipped out fast.