Watch this a 1950’s era food conveyor in action at the Onyx Coffee Lab, located within The Momentary, a new contemporary art space satellite to Sam Walton’s Crystal Bridges Museum of American Art.

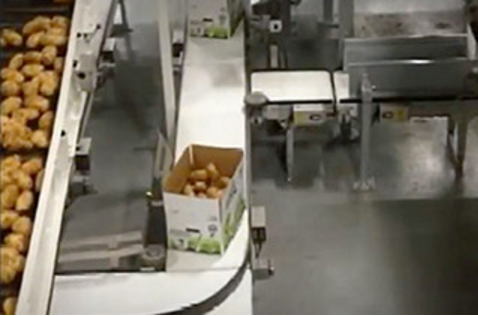

Food Conveyor Systems

Our modular SmartMove® Conveyor systems are sanitary, safe and easy to operate. Our food conveyors meets FDA food standards and can be washed down for easy maintenance. All systems arrive plug & play ready and can be installed right out of the box, without the need for technicians. Just plug into a standard wall outlet and you are up and running, fast.

The Conveyor Industry’s Best Food System Options:

The Conveyor Industry’s Best Food System Options:

- Washdown

- Clean Line

- Work Station

- S Curve

- Long or Short Line

- 90 Degree Turn

- Multi Lane

- Multi Level

- Sorting

- Settable Unit Counting

- Packaging

- Accumulation

- Photo Eye & Infra Red

- Incline or Decline

Clean Lines

Clean Lines

Our systems feature anodized aluminum construction, combined with FDA approved belting materials make what we call our clean line conveyor. Our anodized aluminum conveyors are more cost effective and lighter weight than stainless conveyors.

Hot, Frozen, Heavy or Wet Items Handled

We have 4 types of specially formulated proprietary belting for our food handling systems:

COLD:

Proprietary snap link belting allows for easy maintenance and repair. Link by link construction makes our belting washable and sanitary and it is designed to handle contact with items that are below freezing.

HOT:

Our blended nylon belting is designed to handle high heat and can withstand contact items of up to 350° F (180° C)

HEAVY:

Custom engineered high friction belting for allows for rapid movement of heavy and large items over longer distances.

WATER RESISTANT:

Our plastic chain snap link belting can be sprayed or removed and immersed for easy cleaning.

FDA Compliant

FDA Compliant

Smartmove® Conveyors custom engineers FDA approved conveyor systems meet or exceed sanitary standards.

Customized Features For Any Process

SmartMove® systems are the best food conveyors at they can be equipped with just about any feature to allow for a diverse number of processes like 90 degree turns, sorting bins or adjustable guides that move product from lane to lane. The guide rails can slide in and out according to product width. Variable speed motors allow for exact timing, while our photo eye sensors provide exact counts for sorting and accumulation. Our system keeps your assembly lines moving while wrapping or freezing packaged food items. (Some food restrictions may apply).

CLICK HERE to “Spec Out” a custom conveyor system. Built to order & shipped out fast.