SmartMove® Conveyor’s modular systems can easily be added to or shortened. Our heavy duty high performance machine shop pinned conveyor belting allows for easy removal, cleaning or adding flights. Taking one row out may be necessary if heavy loads have been used daily or after years of use. In the video below, the simple and quick step by step process is explained:

Our heavy duty conveyor belting allows for easy maintenance and fast repair due to it’s pinned construction which is also easy to clean. A patch kit is sent with every conveyor as well as an owners manual to assist in this process.

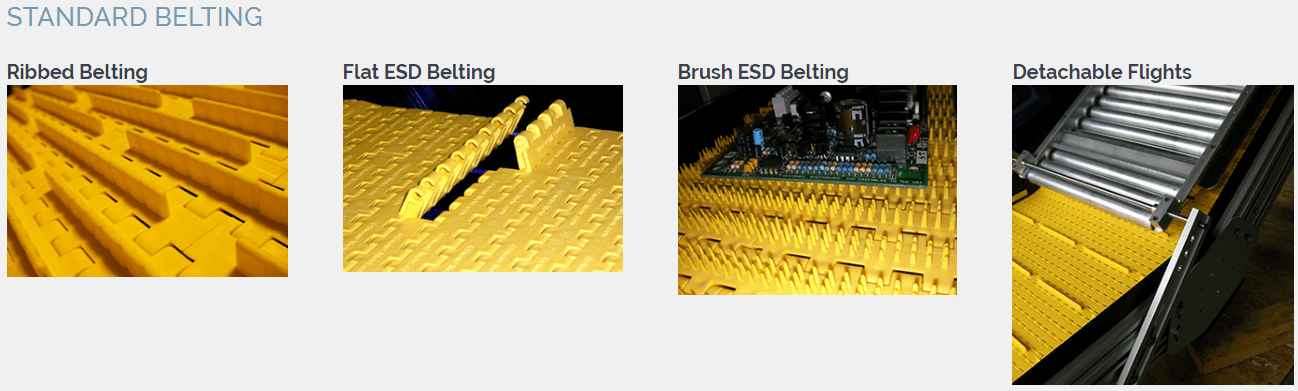

SmartMove offers several standard belt types to choose from like ribbed, ESD (flat & brush), detachable flights and custom engineered belting.

Additional belting types include:

Accumulation Belting – Low friction with high density roller design.

Flat Top Pinned Belting – For heavy loads: high performance pins for higher speeds and longer wear life.

Food Belting – FDA and USDA approved.

Cooling Belting – Specially formulated proprietary blend of nylon Can withstand contact temperatures up to 350° F (180° C).

High Friction Belting – Used for secure handling. Maintains pack spacing and prevents package skewing during conveyor transfer.

Call: 800.581.2876 or click here for further assistance, or to place an order now.